1.Prepare tools and materials

Before grinding, the following tools and materials need to be prepared:

Grinding tools: Select appropriate grinding tools, such as grinding wheels, according to the processing requirements.

Machine tools: Select machine tools with grinding functions, such as surface grinders, cylindrical grinders, etc.

Workpieces: Parts to be processed.

Gages: Tools used to measure the size and shape of workpieces.

Cutting fluid: Used to cool and lubricate the grinding process.

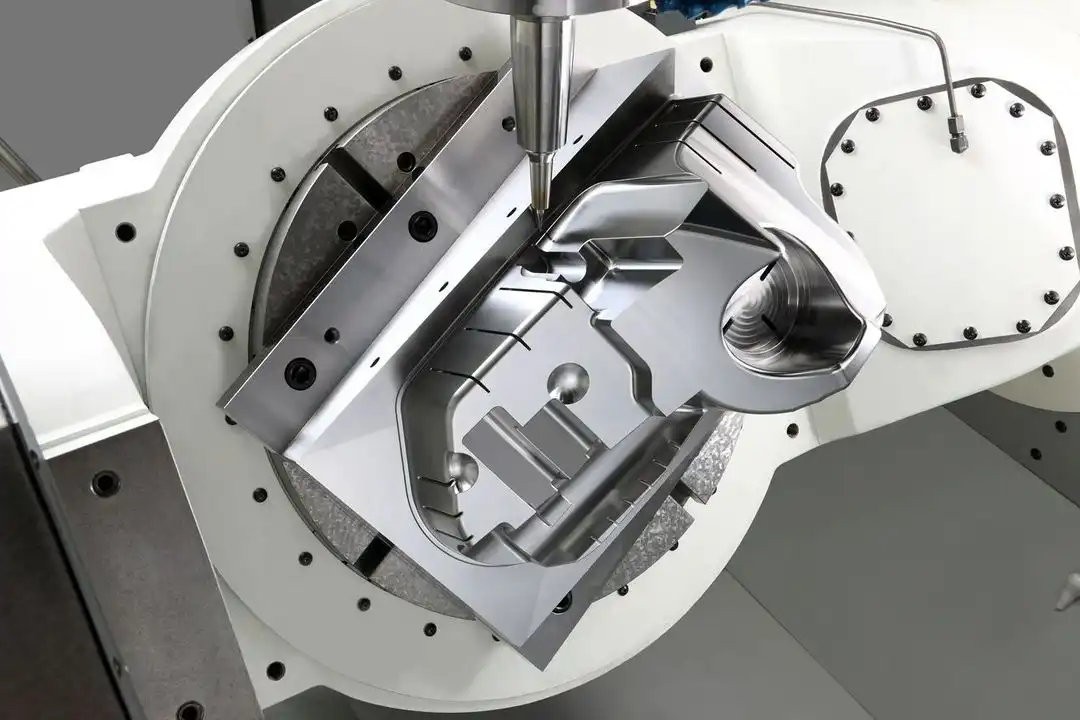

2.Clamping the workpiece

Install the workpiece on the fixture of the machine tool to ensure the position and posture of the workpiece are accurate.

3.Adjust machine parameters

According to the processing requirements, adjust the machine tool parameters, such as grinding wheel speed, feed speed, etc.

4.Start grinding

Start the machine tool and perform grinding. During the processing, the operator needs to pay attention to the grinding situation at all times and adjust the cutting parameters according to the actual situation.

5.Measurement and inspection

After the grinding is completed, use the measuring tool to measure and inspect the workpiece to ensure that the processing quality meets the requirements.

6.Maintenance and care

Maintain and care the grinding tool to ensure the cutting performance and life of the grinding tool. At the same time, perform regular maintenance on the machine tool to ensure the accuracy and stability of the machine tool.